Burbank’s Premier Certified Collision Repair Specialists

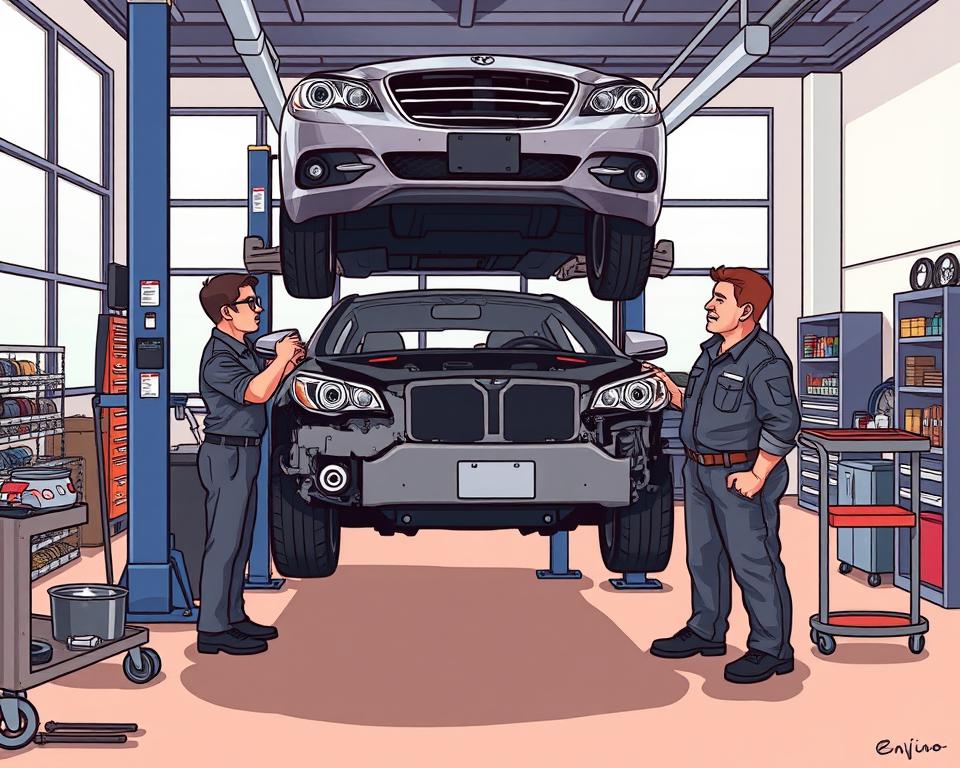

Have you ever thought about what makes a certified collision repair expert to surpass a standard auto body shop? In Burbank, drivers often face accidents, making the choice between a temporary repair and long-term problems vital. Certified collision repair in Burbank goes beyond mere cosmetic restoration. It ensures your vehicle’s safety and performance are returned to peak condition.

US Auto Collisions is a top contender among Burbank’s auto collision specialists. They are committed to delivering the best car repair experience in Burbank. This article will showcase why selecting certified professionals is crucial for your vehicle’s future. It will also illustrate how US Auto Collisions can guide you through an accident’s aftermath with certainty.

Major Takeaways

- Recognizing why certified collision work matters.

- US Auto Collisions is a premier choice for vehicle restoration.

- Quality service leads to enhanced safety and vehicle performance.

- The importance of choosing knowledgeable collision repair shop near me Burbank.

- Ways Burbank’s top repair shop aids in post-accident recovery.

Introduction to Collision Repair in Burbank

Following a crash, collision repair in Burbank becomes essential. Motorists here encounter everything from minor fender benders to major collisions, from small dents to major impacts needing extensive repairs. It’s essential to address vehicle damage accurately to ensure peak performance and safety.

Auto body centers in Burbank prioritize top-tier service. They have the expertise and tools to bring cars back to pre-crash condition. Whether it’s paintless dent correction or structural alignment, they offer customized solutions for each customer.

Local drivers appreciate bespoke repair services. Vehicle owners appreciate shops that provide expert care and understand their specific needs. This fosters confidence and happiness, key in the repair process.

With more cars on the streets and shifting population, demand for trustworthy repairs rises. Local trends show a rising awareness of the need to maintain vehicle integrity. This drives more people to seek professional help after accidents.

The Importance of Certified Collision Repair

Certified collision repair is vital for restoring vehicles to their pre-accident state. It follows rigorous guidelines, ensuring repairs are performed correctly and securely. Experts at US Auto Collisions have the expertise and credentials to work on all types of vehicles. They use the most advanced tools and techniques.

OEM components offer a major benefit in certified repairs. These parts maintain the vehicle’s performance as specified by the manufacturer. This focus on quality boosts the vehicle’s safety and extends its lifespan.

Choosing non-certified collision services poses risks. Without certification, there’s less accountability and adherence to safety standards. Vehicles not repaired to these standards may have compromised integrity, posing hazards to drivers and passengers.

Opting for professional car repair in Burbank ensures safety, quality, and reliability. Customers can trust trained experts to deliver the best results for their vehicles. This brings peace of mind after a collision.

Why US Auto Collisions Stands Out

When you’re dealing with the aftermath of a car accident, picking the right collision center is key. US Auto Collisions is a standout choice, known for its commitment to excellence and client care. They go beyond the standard, making them a top pick for Burbank drivers.

Their alliance with major brands, like Mercedes-Benz, is a notable advantage. This ensures repairs are done with precision and the latest techniques. Their advanced technology allows for accurate diagnostics and repairs, ensuring vehicles are returned to factory specs.

The team at US Auto Collisions is both friendly and knowledgeable. They assist clients every step of the way, keeping them informed at every step. This approach not only fosters confidence but also offers reassurance when it’s most needed. Choosing US Auto Collisions means you’re opting for quality and expertise.

Certified Collision Repair in Burbank

In Burbank, certified collision repair services ensure every vehicle gets top-notch care. Auto body shops in Burbank offer specialized techniques like chassis alignment and glass replacement. These services are crucial for restoring safety and performance.

Staff here receive rigorous training to uphold industry benchmarks. They use the latest technology, following manufacturer specifications for quality repairs. This expertise leads to exceptional service and customer satisfaction.

Customer support is key throughout the repair process. Clients get clear updates from the start to the final inspection. This commitment to transparency fosters reliability, making these auto body shops a trusted option for quality repairs.

Top Features of Auto Body Shops in Burbank

When looking for an auto body shop in Burbank, it’s important to know what makes the best ones stand out. High-tech diagnostic equipment allows for exact damage evaluation and precise fixes. This level of precision is what sets top auto body shops apart.

They provide comprehensive services from repainting to full refinishing. This ensures that customers get all the care their vehicles need. Excellent customer service is also critical, building trust and encouraging customers to return. Shops that focus on customer support tend to create a more positive experience.

Efficient insurance claim processing is another key feature. Shops that handle paperwork well can greatly reduce customer stress. Green methods are increasingly popular among eco-conscious drivers.

Lastly, looking at client satisfaction metrics can give valuable insights. Shops that actively seek feedback and make improvements based on it show a dedication to excellence. This focus on improvement strengthens their local standing.

| Top Features | Importance |

|---|---|

| Advanced Diagnostic Tools | Enables accurate damage assessment |

| Variety of Services | Comprehensive vehicle care options |

| Excellent Customer Service | Builds trust and repeat business |

| Efficacy in Insurance Claims | Reduces customer hassle and stress |

| Eco-Friendly Practices | Appeals to environmentally conscious consumers |

| Client Satisfaction Metrics | Indicates commitment to quality and improvement |

Client Reviews and Success Stories

Client reviews at US Auto Collisions showcase the impact of expert repairs in Burbank. Clients often share their experiences, praising the exceptional quality of the repair services. They note how their vehicles were returned to their original condition, surpassing expectations. This shows the team’s capability and instills confidence in their work.

Success stories also showcase the team’s dedication to restoring vehicles after accidents. Customers express their relief and satisfaction when they get their cars back. They often comment on the completeness of the restoration and the attention to detail. These stories prove US Auto Collisions’ commitment to excellence in the collision repair process.

Positive feedback from clients enhances their local credibility. These stories help build trust among those seeking professional car repair in Burbank. They emphasize the transformative experiences, reinforcing the business’s credibility. They also highlight the importance of quality service in delivering peace of mind.

Side-by-Side Comparison of Burbank Collision Shops

Choosing the right repair shop starts with comparing Burbank collision centers. Each center has its own set of credentials, offerings, ratings, and costs. Knowing these differences is key to finding the right fit for your vehicle’s needs.

| Collision Center | Certifications | Services Offered | Average Customer Rating | Pricing Structure |

|---|---|---|---|---|

| US Auto Collisions | ICAR Certified | Full-service repairs, paintless dent repair, detailing | 4.8/5 | Competitive with insurance support |

| Auto Body Pros | ASE Certified | Collision repair, frame straightening, painting | 4.5/5 | Standard market rates |

| Reliable Collision | OEM Certifications | Bodywork, glass repair, towing | 4.3/5 | Higher-end pricing |

With its comprehensive offerings and top ratings, US Auto Collisions leads the pack. For those seeking a trusted Burbank auto collision specialist, examining these options is critical. Whether you focus on reviews or service types, comparing centers helps you choose the best for your vehicle’s repair.

Coverage & Warranty

US Auto Collisions simplifies the complex world of insurance for customers. They work with leading insurers to offer efficient service and support. This knowledge can reduce stress during a challenging time.

At a collision center near me, customers can expect clear communication about coverage and costs. The staff at US Auto Collisions are experienced with multiple insurance plans. They make it easier for clients to understand their options and obligations.

They back repairs with strong warranty programs. This warranty provides a safety net, ensuring vehicles meet the highest standards post-repair. These guarantees reinforce confidence in certified repairs, giving peace of mind to those needing vehicle restoration.

| Insurance Provider | Claims Process Time | Warranty Offered |

|---|---|---|

| State Farm | 1–2 Weeks | Lifetime Warranty on Repairs |

| Geico | 1 Week | 3-Year Warranty on Parts |

| Progressive | 2 Weeks | Limited Lifetime Warranty |

| Allstate | 1–3 Weeks | 5-Year Warranty on Paint |

US Auto Collisions is a reliable choice for quality collision repair, thanks to their insurance information and solid warranties.

Wrapping It Up

Certified collision work in Burbank matters greatly. Opting for a certified professional guarantees your vehicle gets top-notch care. This care includes using the latest techniques and materials. It not only brings back your car’s original look but also ensures its safety and performance.

Known for outstanding service, US Auto Collisions leads the Burbank market. Their focus on quality and trustworthiness has earned them a solid reputation. They are the preferred for those seeking reliable and certified collision repair in Burbank.

When you need collision repair, US Auto Collisions offers unmatched convenience and professionalism. They aim to not just fix your vehicle but to give you peace of mind. Their certified services are something you can trust.

Frequently Asked Questions

Define certified collision repair.

Certified collision repair is a set of processes and standards followed by auto body shops like US Auto Collisions. It aims to restore vehicles to their pre-accident state. Using OEM components and strict protocols ensures optimal outcomes.

Why is it important to choose a certified collision repair shop in Burbank?

Choosing a certified center guarantees expert workmanship. They adhere to industry standards, improving safety, longevity, and performance. This reduces the risks of subpar repairs.

What types of services do certified collision repair centers offer?

Certified collision repair centers offer various services. These include frame straightening, paintless dent repair, glass replacement, and expert refinishing. They address different levels of damage from accidents.

Why choose US Auto Collisions?

US Auto Collisions excels with advanced diagnostic tools, outstanding customer service, and partnerships with major insurance providers. They also focus on eco-friendly practices. Ongoing education and premier tech guarantee quality outcomes.

What can I expect during the insurance claims process at US Auto Collisions?

They assist you step-by-step with claim filing and approvals. They have partnerships with major insurance providers. This makes filing claims and getting repairs efficiently easier for you.

Warranty coverage at US Auto Collisions?

Yes, US Auto Collisions provides warranties on their repairs. It ensures lasting results and client confidence. Warranty protection underscores their commitment to excellence.

Finding top collision centers in Burbank?

Check digital testimonials and scores. Compare services and seek out certified auto body shops with strong credentials and positive feedback, like US Auto Collisions.

What do customer testimonials say about US Auto Collisions?

Customer testimonials praise the service, quality repairs, and positive experiences at US Auto Collisions. Numerous customers report flawless, factory-like restorations. They appreciate the thorough care during the repair process.