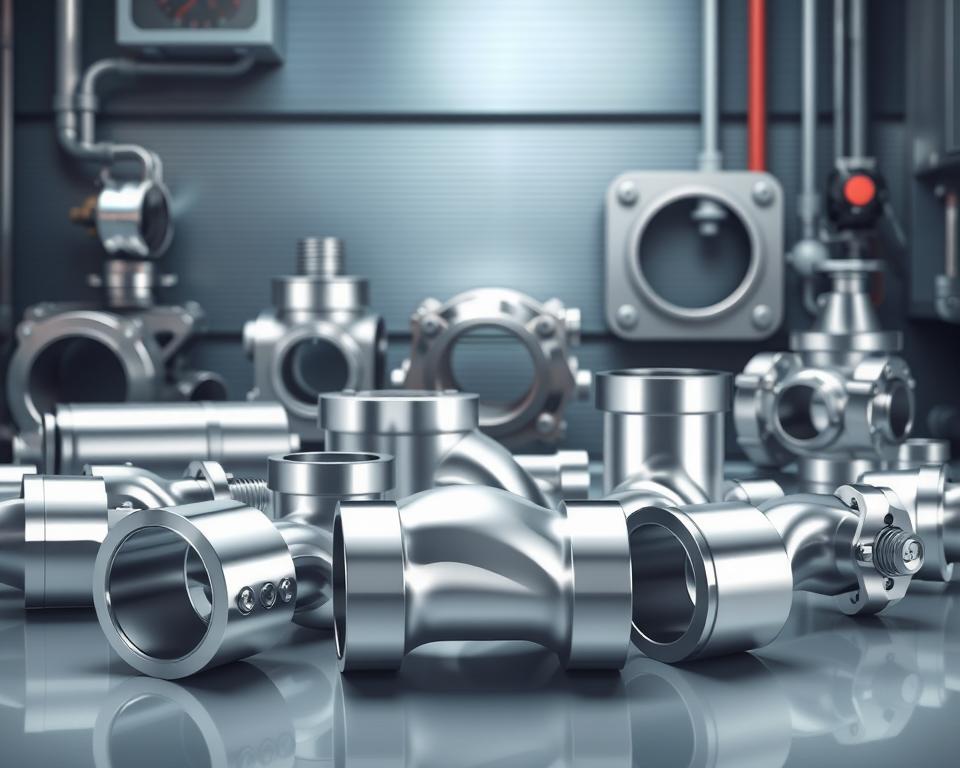

High-End Tri-Clamp Clean-Flow Fittings for Maximum Cleanliness

In industries where contamination can be fatal, even micro-fissures count. Hence, companies like Installation Parts Supply provide meticulously designed solutions minimizing contamination. Such hygienic connection systems blend long-lasting strength with seamless assembly, establishing them as a top choice for workplaces that can’t afford compromises.

These components do more than preventing leaks – they’re built to meet the tough needs of edible-product processing, drink-line facilities, and pharma operations. Forged from chemical-resistant stainless, they handle repeated washdowns while maintaining structural integrity. The design philosophy mirrors industry leaders like Alfa Laval, emphasizing Tri-clamp fittings catalog smooth surfaces and rapid breakdown.

Why are these fittings different? Think single-handed setup and equipment-free care. Operators welcome the straightforward build during fast-paced operations, while managers prioritize repeatability across pipelines. Every piece passes through tight verification to meet FDA and 3-A Sanitary Standards.

Central Ideas

- Chosen by specialists for leak-proof performance in sensitive settings

- Made from premium stainless steel for lasting durability

- Makes it easy to meet food safety and pharmaceutical regulations

- Decreases idle periods through no-tool fitting and washdown

- Strengthened with testing programs meeting global benchmarks

Overview & Primary Benefits

Dependable joints are the backbone of hygienic processes. Installation Parts Supply develops components that merge fine-tuned tolerances with operational practicality. Their solutions provide airtight performance while simplifying maintenance workflows—critical for industries where speed and safety intersect.

Elite Grade & Hygiene Compliance

Every piece faces intensive trials to match global requirements. The alloys defy deterioration, even after frequent autoclave runs. Seamless seals prevent bacterial growth, a feature valued by dairy processors and pharmaceutical manufacturers alike.

These couplings mirror the standards of leaders like Alfa Laval, guaranteeing smooth surfaces and uniform dimensions. Configurable designs adapt to existing setups, minimizing conversion fees. Operators experience 30% faster fitment compared to traditional threaded systems.

Supplier-Specific Advantages

Made-to-order builds sets this supplier apart. Looking for unusual geometry or rare plating? Their team teams up with buyers to produce precise builds. Rapid fulfillment and 24/7 technical support prevent bottlenecks.

The perks stretch further than strength. Tool-free disassembly cuts downtime during sanitation audits. Brew houses using these connectors record fewer production stoppages and steady throughput. It’s not just about meeting regulations—it’s about leapfrogging requirements.

Technical Data and Build Traits

High-accuracy design meets flexibility in modern industrial systems. Installation Parts Supply fabricates components that balance exact measurements with versatile designs. Their mode provides seamless integration into current lines while retaining exacting sanitary guidelines.

Bespoke Metals & Finishes

Each application demands something different. That’s why metals offered cover 304 as well as 316L, opted for strength and corrosion resistance. Surface treatments like electro-buffing produce mirror-like smoothness, reducing bacterial adhesion by up to 40% compared to standard finishes.

| Finish Type | Key Feature | Compliance |

|---|---|---|

| Electropolished | Ultra-smooth surface | ASME 3A, ISO 9001 |

| Mechanically Polished | Cost-effective shine | 3-A Sanitary Standards |

| Bead-Blasted | Non-reflective texture | FDA Food Code |

Manufacturing processes utilize beam-based sensors to confirm uniform wall thickness. Tight tolerances (±0.005″) avoid frail sections in elevated-pressure rigs. During quality checks, components undergo X-ray scans and pressure tests to uncover microscopic flaws.

Customization surpasses looks. Clients order precise degree-turns, flange sizes, or specialized coatings for chemical resistance. These made-to-order choices help industries meet evolving safety regulations without overhauling the whole plant.

Tri Clamp Sanitary Fittings: Installation and Applications

Modern high-speed plants demand components that fit fast yet perform reliably. These coupling sets shine in environments where efficiency partners with purity. Their design does away with heavy tooling, permitting teams to focus on productivity rather than setup struggles.

Quick-Install Workflow

Coupled flange rims and a centered gasket produce foolproof seals in seconds. Staff set the parts, seat the squeeze band, and lock by grip – no wrenches required. This method lowers setup slips while maintaining consistent pressure across the joint.

| Step | Traditional Method | Modern Solution |

|---|---|---|

| Alignment | Thread matching required | Flanged ends self-center |

| Sealing | Multiple tape layers | Single food-grade gasket |

| Securing | Torque wrench needed | Hand-tightened mechanism |

Versatile Bridges Across Equipment

Connecting clean pipes to vessels, these interfaces bridge diverse components effortlessly. The uniform design fits into various diameters, supporting speedy swaps during product changeovers. Dairy plants typically adopt them to change between cleaning cycles and production runs without hiccups.

Upkeep units favor how components split for thorough sanitation. Smooth surfaces prevent residue buildup, while the smooth bore stops microbe pockets. Weekly cleanings require 50% less effort compared to older connection methods.

Market Adoption & Standard Adherence

Spanning artisan beer halls to inoculation plants, modern facilities use hardware that match assorted tasks while adhering to tough regulations. Installation Parts Supply provides solutions valued across sensitive industries where product purity can’t be negotiable. Their designs link productivity to compliance, forging setups that work under strain.

Edibles, Drinks, and Drug Industries

Throughout refreshment operations, rapid-swap fittings make alternating between flavors and sanitizing simple. Breweries rely on custom tees to manage complex flow paths while eliminating cross-mix hazards. Pharmaceutical manufacturers trust airtight seals to protect sensitive compounds during sterile transfers.

These links arrive in many diameters to match piping layouts, from pilot plants to massive brewhouses. Dairy processors praise how standardized parts minimize stoppages during equipment upgrades. Even small shifts in production processes are absorbed through modular designs.

Certification Under ASME-ISO-3A

Every component hits or surpasses benchmarks set by global organizations. ASME-certified materials manage hot media in pasteurization systems, while ISO-compliant finishes reject microbial film. The 3-A symbol confirms appropriateness for direct contact with consumables.

Tri-Clamp couplings illustrate the dedication. Their uniform dimensions ensure leak-free performance across automated lines. Third-party audits validate supply chain from raw materials to finished goods, giving quality teams peace of mind.

By tracking these benchmarks, facilities simplify audits and pass inspections effortlessly. It’s not just about sidestepping fees—it’s about securing customer faith through obvious compliance.

Wrap-Up and Future Steps

Selecting parts that pair output and rules guides plant achievements. Installation Parts Supply provides systems fusing robustness with sterile engineering, securing leak-free performance across food, pharma, and beverage environments. Their products conform to rigorous standards while making daily work simpler through simple fitment.

With variants in steels and textures, solutions tailor to distinct facility goals. Whether carrying thermal streams or endless sanitation loops, material choices and surface treatments optimize longevity. Professionals value the broad range of couplings made for particular throughput and pressure.

Ordering proves straightforward, with specialist help on hand to pair process demands. Express delivery and minimized wait times minimize downtime during upgrades or replacements. Routine maintenance becomes effortless thanks to tool-free disassembly and smooth surfaces that resist residue buildup.

Looking to improve operational trust? Get in touch with Installation Parts Supply to explore tailored configurations – from tri-clover to tri-clamp variants – supported by top-tier QA. Their team makes sure you satisfy today’s rules while gearing up for next-gen demands.