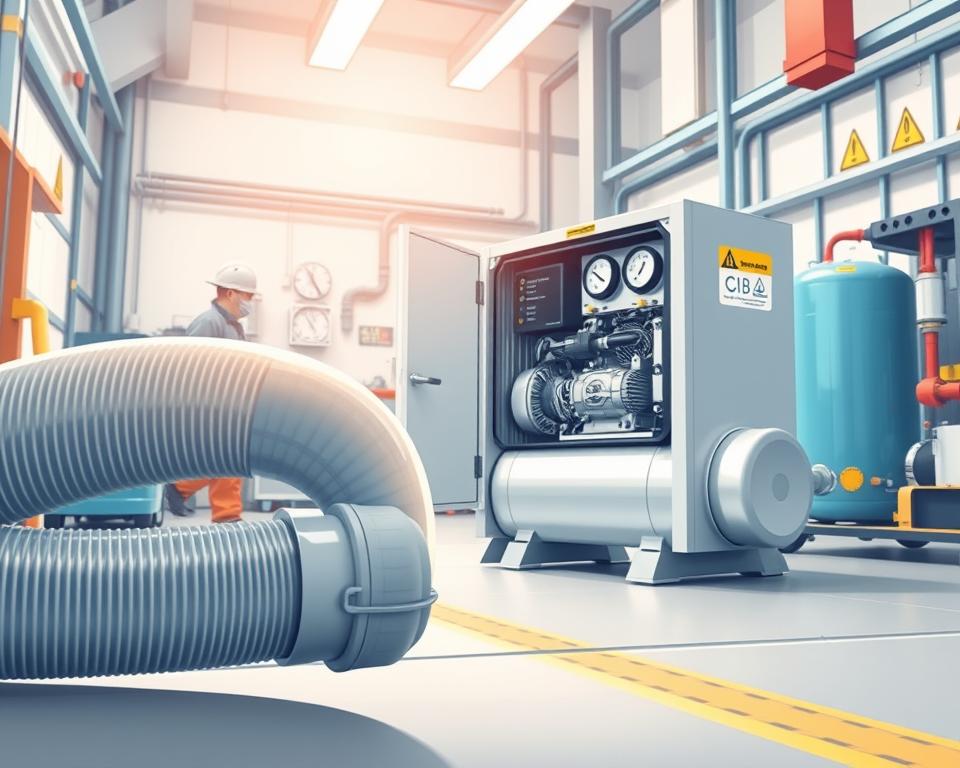

PVC Pipe for Air Compressor Lines: Your Complete Guide

A burst compressed air line can discharge energy comparable to a stick of dynamite—did you know? Many facilities still use piping systems made from risky materials, unaware of the dangers. Read on to discover why PVC for air lines choices demand top-tier safety.

Even as interest rises, OSHA bans these materials for above-ground compressed air. Over time, exposure to oils and temperature changes weakens them, leading to catastrophic failures. Even at “safe” pressure ratings, the risk of explosions remains high.

Turn to Installation Parts Supply for sturdy aluminum systems. Investing in proper materials avoids costly fines and keeps workplaces secure. Let’s explore how to build a safer system.

Important Lessons

- OSHA bans certain materials due to explosion risks.

- Pressure ratings drop as temperatures fluctuate.

- Long-term exposure makes pipes prone to brittle breaks.

- Aluminum lines deliver a far safer option.

- Proper investment prevents costly fines and accidents.

The Risks of PVC in Air Compressor Lines

All major brands advise against certain plastics in compressed air. A breach in a pressurized air line unleashes explosive power, unlike water. Material selection is the linchpin of air-system safety.

- Brittleness: Sub-freezing temperatures turn materials brittle, increasing fracture risks.

- Adhesive failures: Oil contamination and heat cycles break down glue bonds.

- Misleading ratings: Pressure capacity drops 50% at 110°F—most workshops exceed this.

A facility faced a $110k penalty when PVC shattered and harmed employees. Don’t forget, compression heat cuts into rated safety margins.

“Above-ground use of certain plastics for compressed air violates OSHA standards due to explosion risks.”

Steel and aluminum curve under stress instead of shattering. PVC shards fly far and fast, causing collateral damage.

Constant temperature swings in shops speed up pipe aging. Over 10 years, UV exposure and chemical interactions further compromise integrity, turning minor leaks into major hazards.

Best Materials Instead of PVC for Air Lines

Modern aluminum systems beat old-school piping on both safety and performance. With 90% fewer leaks than black pipe, they’re a top choice for modern facilities. Aluminum’s lightness and anti-rust traits prolong system life.

Threadless modular aluminum assemblies speed assembly. Installation Parts Supply stocks ready-to-snap aluminum modules. A car plant saw a 40% drop in labor expenses after aluminum installation.

- Copper: Best for cleanrooms due to natural antimicrobial properties. Requires soldering expertise.

- Stainless Steel: Stainless steel stands up to salty, moist conditions.

- ABS/HDPE: Plastic choices like ABS or HDPE handle harsh chemicals.

“Our aluminum retrofit reduced energy waste by 15%—paying for itself in 18 months.”

Torque matters. Cracks from overtightening and leaks from under-tightening are common. Follow manufacturer specs—typically 25–30 ft-lbs for aluminum joints.

Use NSF-certified materials when air quality is critical. Choose pipe rated for your specific operating environment.

How to Choose the Right Piping Material for Your Needs

Balance budget, safety, and performance when choosing pipe. Switching to aluminum saved a factory $12k each year. Follow these tips to pick wisely.

| Material | Cost (per ft) | Maintenance | ROI Time |

|---|---|---|---|

| Aluminum | $8.50 | Low | 18 months |

| Black Pipe | $5.00 | High | N/A |

| Copper | $10.20 | Medium | 24 months |

Don’t ignore thermal limits. From arctic chills to high heat, aluminum outperforms. Use stainless steel where solvents are present.

Pro Tip: Use leak-loss math to estimate ROI. Don’t let 10% leakage cost you $3,500 a year.

- Match PSI ratings to your compressor’s output.

- Check OSHA compliance for weld inspections and pressure tests.

- Request a free system audit from Installation Parts Supply.

“Our aluminum retrofit cut energy waste by 15%—paying for itself in 18 months.”

DIY installations work for small shops, but professionals ensure leak-free joints. Check warranties—some pipes include decade-long coverage.

Bringing It All Together

Smart material selection protects life and wallet. Older systems account for 92% of accidents due to degraded piping. Aluminum offers 99.8% reliability, making it a smart long-term choice.

Key takeaways:

- Avoid brittle materials that shatter under pressure.

- Opt for corrosion-resistant metals like aluminum or stainless steel.

- Ignoring standards invites fines and insurance headaches.

Time to make the switch? Installation Parts Supply provides same-day quotes and limited-time discounts on starter kits. Request your free template or emergency service today.

Make safety your piping priority—act today.